Recently, Hitachi has developed a 48V lithium-ion battery pack with high

power output suitable for small-displacement vehicles for medium-hybrid

vehicles. Due to its system's good fuel consumption reduction effect and high

cost performance, it is expected to be popular in China and Europe. The 48V

system currently on the market is mainly used for micro-hybrid and weak hybrid

vehicles. The lithium-ion battery pack developed by Hitachi this time further

expands the application of the 48V system in the field of hybrid vehicles.

48V system concept

In order to more effectively save energy, reduce emissions, and improve

fuel economy, people have found a new system between the transformation of the

engine itself and the replacement of a completely new power system, that is, the

hybrid power system. Nowadays, a hybrid system is widely used, that is, in a car

with a gasoline and diesel engine, an electric motor is added, and the two

engines work together. The initial micro-hybrid system is to add a belt-driven

starter motor (BSG) to the starter motor (usually 12V) on the traditional

internal combustion engine. The motor is a stop-start integrated motor to

control the start of the engine. And stop, thereby canceling the idle speed of

the engine, reducing fuel consumption and emissions, that is, the so-called 12V

micro-mixing system has the function of automatic start and stop.

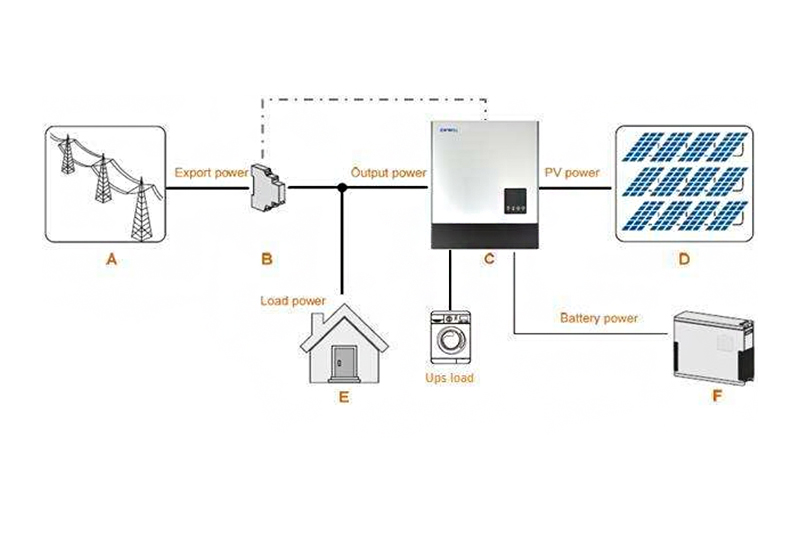

The 48V system is an improvement to the 12V micro-hybrid automatic

start-stop system. The voltage of the system is 48V. The traditional lead-acid

battery is replaced by a power lithium-ion battery with an energy of less than

one kilowatt-hour, and the traditional starter motor and generator are replaced

by a BSG motor. It is equivalent to an enhanced version of the automatic

start-stop system. In addition to the automatic start-stop function, it can also

provide auxiliary power when necessary.

The source of the 48V system

The concept of the 48V system originated from the joint launch of several

German vehicle manufacturers including Audi, BMW, Daimler, Porsche and

Volkswagen in 2011 and the development of the LV148 standard. In June 2013, the

European Union approved the 2020 carbon dioxide emission standard, which

requires that the average carbon dioxide emission level of new cars be

controlled at 95 g/km by 2020; if European car manufacturers cannot meet the

requirements for CO2 emission restrictions in the future, they will face A fine

of up to 95 Euros per gram per car per excess. This compulsory standard has

prompted OEMs and component suppliers to reduce the fuel consumption of vehicles

from different technical routes. The 48V system has become the focus of

attention in the industry due to its increased limited cost and significant

energy-saving and emission-reduction advantages.

Compared with the advantages of the 12V micro-hybrid system, Hong Yinglin,

Delphi Parker’s Asia Pacific New Energy Product Manager, gave us an example:

“For example, air conditioners. When a traditional car is waiting for a red

light, the engine is idling, and the belt-driven air conditioner compressor can

Continue to work, the air conditioner will still be cooled. But for cars with

start-stop function, they need to switch to electric air conditioners when they

wait for the red light, otherwise the passengers have to endure the environment

without air conditioning when the red light or traffic jam. An electric

air-conditioning compressor The minimum power is 2.5kw. If 12V is used for power

supply, the grid will be unbearable, and 48V will be no problem. In addition,

the 48V side can also provide power for active suspension, electric steering,

electric heaters, etc."

At present, the mainstream in the Japanese market is a strong hybrid

vehicle equipped with a high-voltage battery of more than 100V, which uses a

lithium-ion rechargeable battery module of more than 100V. Although it can

greatly improve the fuel efficiency of hybrid vehicles (HEV), it is a special

component And the cost of withstand voltage components is high. Using a 48V

system will also increase the cost, but compared to the cost of a pure electric

vehicle or a strong hybrid car, the 48V system can save 40% to 60% of the cost,

and the 48V lithium-ion rechargeable battery module can also increase the cost

by 10-15%. Fuel efficiency.

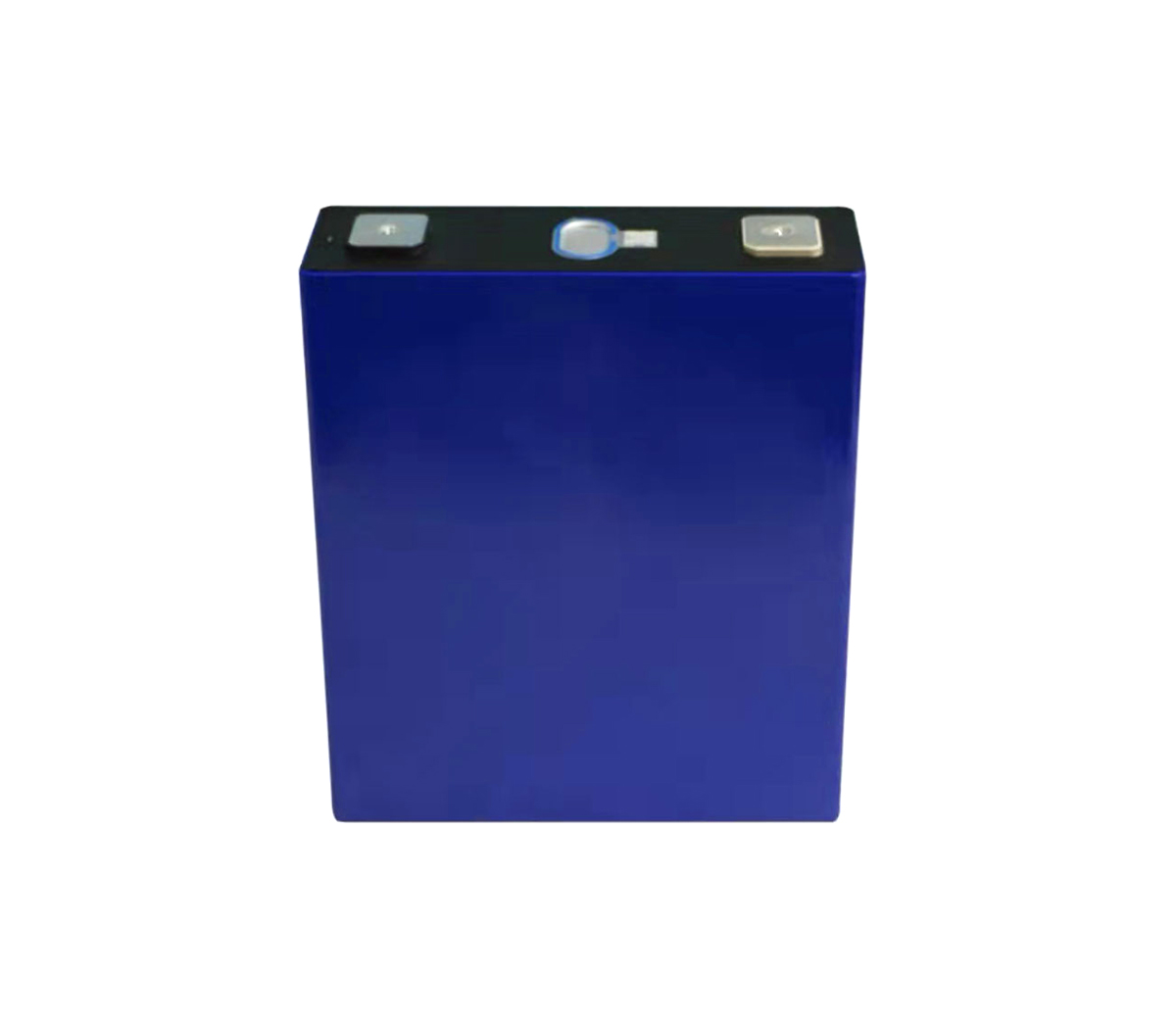

One of the keys to the 48V system specification is the lithium-ion battery

technology, which can provide a higher (3 times) energy density than the

lead-acid chemical battery, and reduce the size and weight. The 48V lithium-ion

battery has better charging performance and can more efficiently store the

energy recovered by the car’s braking, which can provide more and more

electronic loads (such as front seat heating, heated windshield, rear Shock

absorber) provides more power. 48V lithium ion battery system application

status

One of the keys to the 48V system is lithium-ion battery technology.

Compared with lead-acid batteries and nickel-hydrogen batteries, lithium-ion

batteries have higher energy density and better charge and discharge

performance. The voltage of lithium-ion batteries is as high as 3.7V. In order

to meet the voltage requirements of electric vehicles, it is necessary to

connect single batteries in series and parallel to form a battery pack to meet

the high-energy and high-power conditions required for electric vehicles. Under

normal circumstances, the car power system regards the battery pack as a single

battery. During the start and stop of the car, the entire battery pack undergoes

frequent charging and discharging processes. The battery pack is composed of

single cells, and the absolute consistency of the battery cells cannot be

guaranteed before leaving the factory. If a battery in the battery pack has

undergone multiple charge/discharge cycles, its state of charge cannot be

periodically balanced with other batteries , It will eventually enter a deep

discharge state, which will cause damage and eventually cause a battery pack

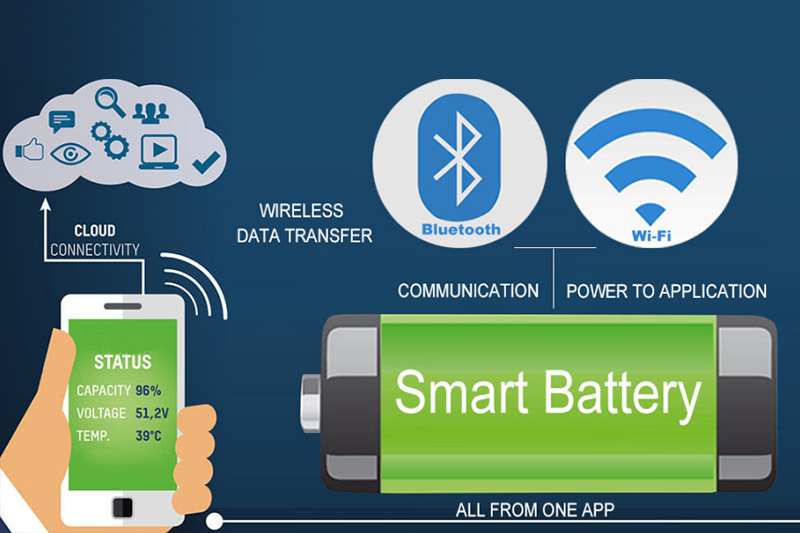

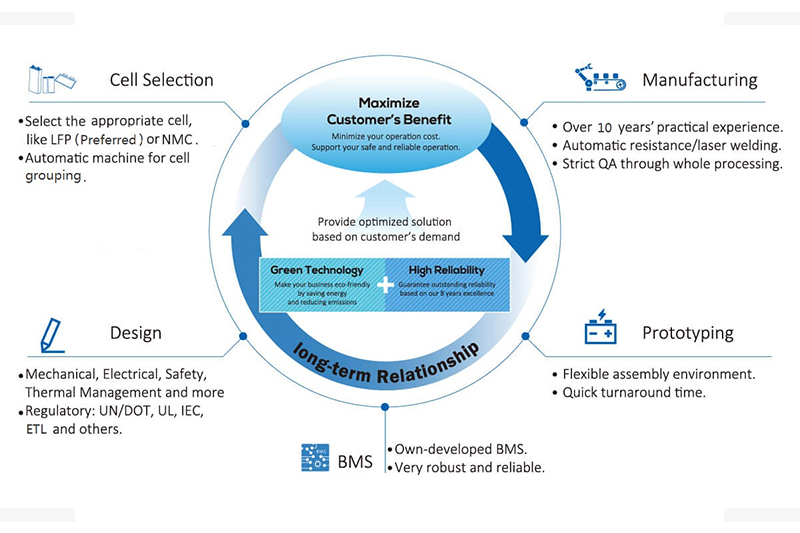

failure. Therefore, we need a battery detection system (BMS: Battery Management

System) to monitor and measure the overall condition of the battery pack and

individual batteries, including voltage, current, and charge. Status, etc., and

replace the single battery in time to extend the endurance and service life of

the battery pack.

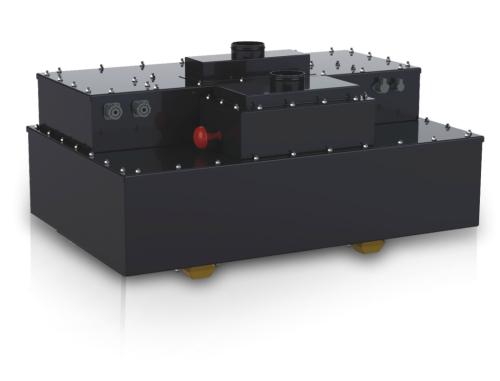

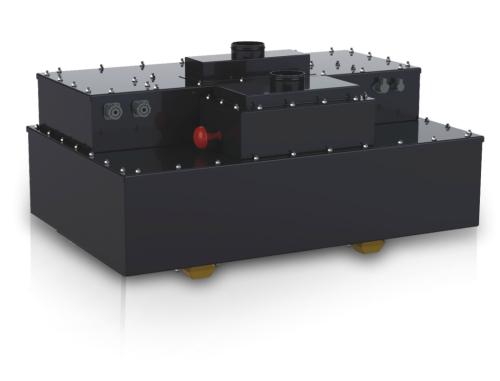

The 48V lithium-ion battery pack newly developed by Hitachi this time

contains BMS substrates, battery cells, relays, and fuse packs in the same box.

It has strong assembly and high reliability. This battery pack can accelerate

and decelerate the vehicle. As well as energy regeneration during braking, it

supports the efficient operation of hybrid vehicles' engines and motors.

At present, the 48V lithium-ion battery packs on the market generally

consist of 12 to 13 single cells, which are mostly used in the field of small

pure electric vehicles such as electric bicycles, electric motorcycles, electric

tricycles, etc., as well as power tools; mainly for vehicles Lithium-ion power

battery manufacturers include AVIC Lithium, CITIC Guoan Mengguli and Wanxiang

Group.

In the field of hybrid vehicles, the 48V lithium-ion battery pack system is

mainly used in micro-hybrid or weak-hybrid systems, and is at the level of

research and development and limited production. In response to the development

of more energy-efficient automotive products, car giants are developing

automotive products that use 48V automatic start-stop systems. The world's

leading industry research organization IHS released a report that by 2025, 48V

mild hybrid vehicles will account for more than half of all hybrid vehicles, and

95% of mild hybrid vehicles will adopt the 48V solution.

The 48V lithium-ion battery pack developed by Hitachi this time can be

applied to moderate hybrid electric vehicles, with higher input power and output

power, and the battery cells have excellent low temperature resistance, and the

output density is the same as that of the previous Hitachi battery cells. 1.5

times, both good fuel consumption reduction effect and high cost performance

have played a role in promoting the popularization of mid-mixed vehicles in

China and Europe.