As a representative company of next-generation power batteries, SES recently released the latest 100 Ah single-cell lithium metal battery. At the same time, it gave a detailed introduction to its industrialization timetable, customer cooperation and listing process.

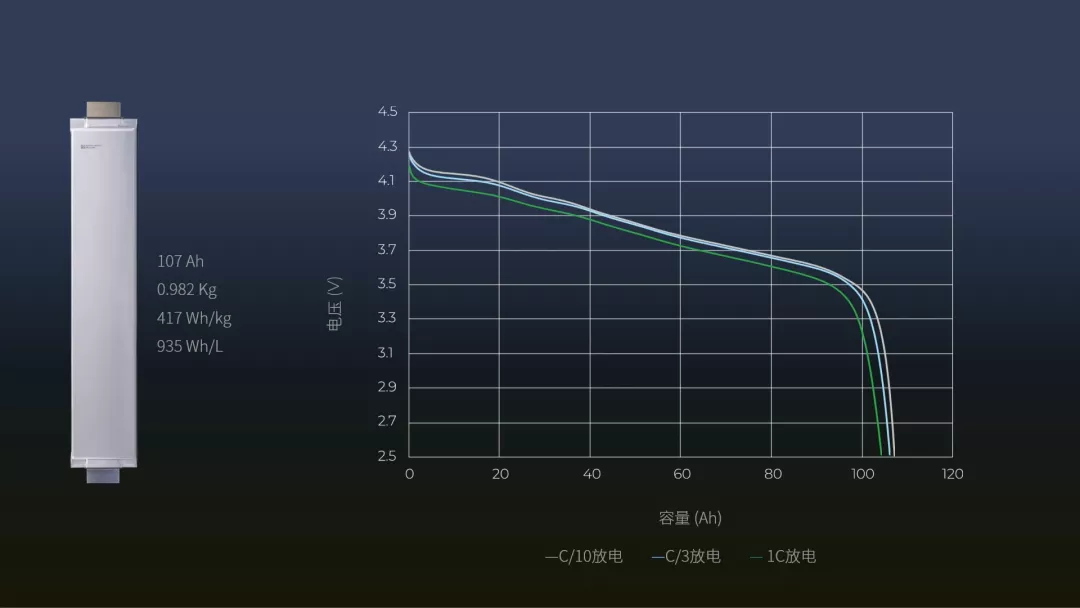

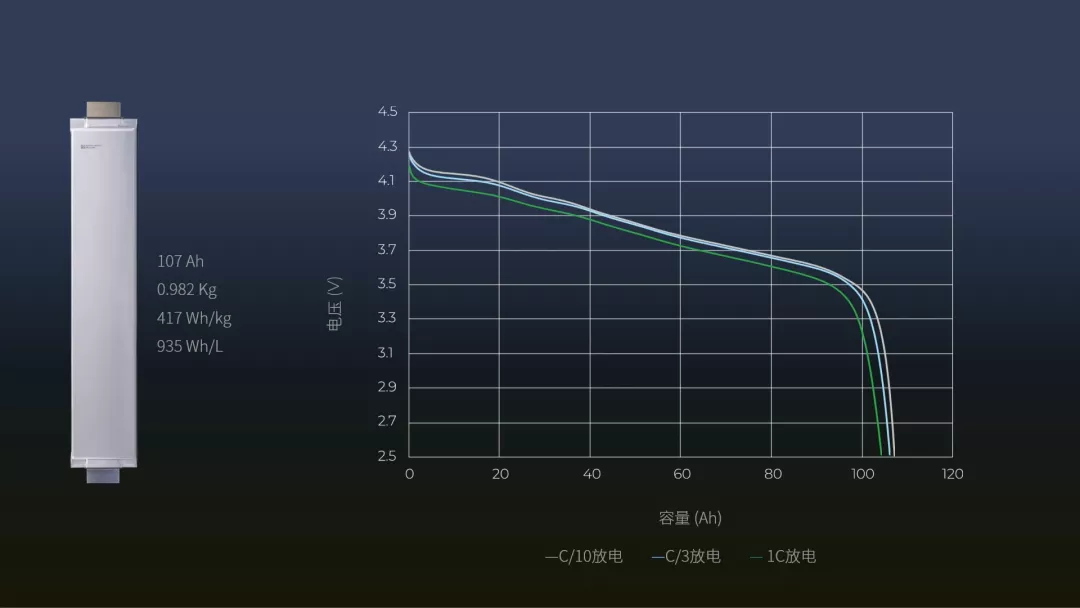

(SES Apollo™ large cell performance data)

Unlike the all-solid-state battery path chosen by its peers such as QuantumScape and Solid Power, SES focuses on hybrid lithium metal batteries.

The idea of SES is that lithium metal batteries are undoubtedly the ultimate direction, but the realization of all solid-state lithium metal batteries is very difficult and industrialization is not realistic. The hybrid lithium metal battery solution maintains the advantages of solid lithium metal high energy density, and at the same time It maintains the same production process and manufacturability as lithium-ion batteries.

Some people in the industry believe that the next generation of power batteries represented by lithium metal batteries has entered a new stage of commercialization from the perspective of product development cycles, car company applications, and capital operations. Because lithium metal batteries have jumped from the initial single-layer, multi-layer, and Ah-level batteries to the car-grade 100Ah battery level, this is the "eve" of commercialization.

SES publicly displayed a single lithium metal battery exceeding 100 Ah for the first time. From the performance index, the Apollo™ 107 Ah battery weighs only 0.982 Kg, has an energy density of 417 Wh/kg, 935 Wh/L, and runs for 10 hours at room temperature, 3 hours and 1 hour discharge test, all showed extremely high capacity and energy density.

From the perspective of engineering manufacturing, SES has mastered a set of core material technologies for the industrialization of hybrid lithium metal batteries, and has explored a complete production process and manufacturing process:

Wide-width lithium metal anode: ultra-thin metal anode manufactured through proprietary intellectual property technology

Composite negative electrode coating: Improve safety through mechanical barrier

Polymer-based diaphragms: highly manufacturable advanced diaphragms

High-concentration liquid electrolyte formula: low volatility and self-extinguishing

High energy density cathode: highly manufacturable advanced cathode technology

This will play a vital role in the subsequent large-scale manufacturing and verification.

Compared with QuantumScape, Solid Power and other companies focusing on solid-state lithium metal batteries, SES took the lead in launching its 107 Ah large cells, which is a very big leap.

The hybrid lithium metal battery selected by SES is more feasible in industrialization. It not only maintains the characteristics of high energy density of lithium metal battery, but also has a higher degree of matching with existing lithium ion batteries in process and manufacturing. This is also the first that SES can take the lead. The root cause of the introduction of 100 Ah-class lithium metal batteries. In fact, many battery companies, including Feng Li New Energy, are also considering or deploying the hybrid lithium metal battery route selected by SES.

The layout of car companies has also become more frequent, which is reflected in two levels: On the one hand, major car companies actively participate in the investment and financing process of solid-state battery companies, and their ambitions are to look forward to the deployment of next-generation batteries. On the other hand, it is accelerating the promotion of technological development and cooperation with battery companies to promote the verification of next-generation batteries.

Taking SES as an example, it is cooperating with General Motors and Hyundai on A samples, and plans to launch A samples of automotive-grade lithium metal batteries next year, provide C samples in 2024, and officially start commercial mass production of lithium metal batteries in 2025.

In order to cooperate with the verification of samples B and C, SES announced at this event that it is building a Shanghai super factory, which is scheduled to be completed in 2023. After completion, the production capacity will reach 1GWh. It will be the world's largest lithium metal battery factory.

(SES Shanghai Super Factory)

The revolution of battery technology is not just a pure technological evolution, it will also subvert the existing industrial structure and industry pattern. For next-generation battery companies like SES, it is necessary to rely on its own technological precipitation, establish a feasible industrialization path, and cooperate with upstream and downstream strategic partners in the industrial chain to step on the market rhythm in order to truly realize the industrialization of new technologies and products. Landing.

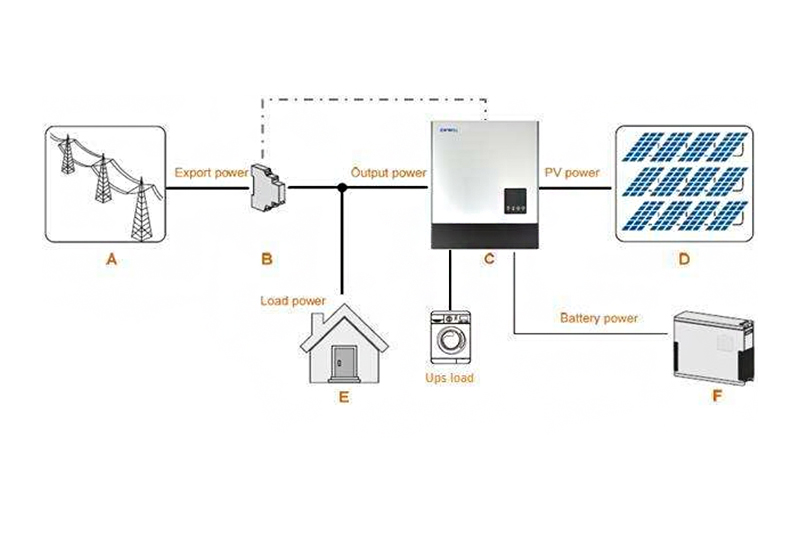

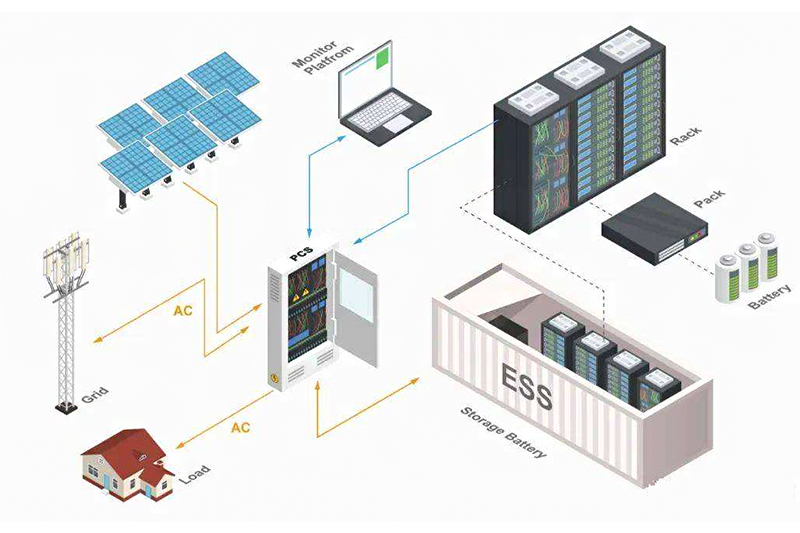

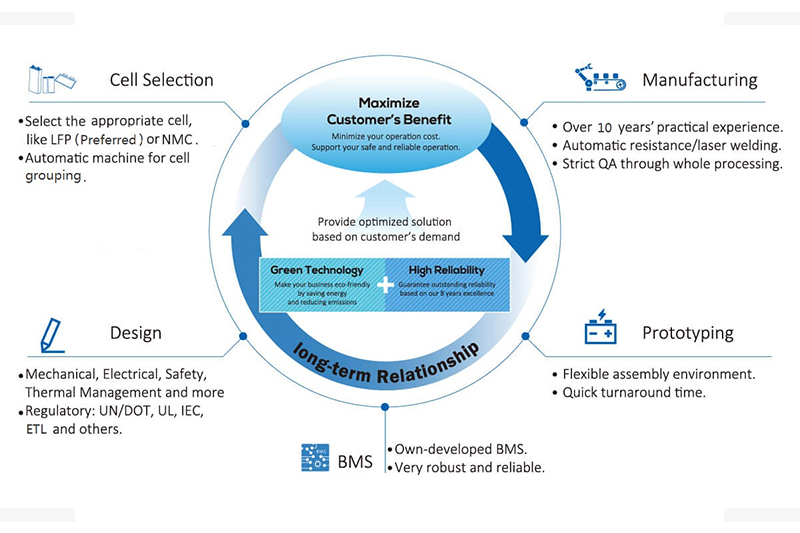

Lithium-ion battery (LIB) has become the main energy storage solution in modern social life. Among them, lithium iron phosphate batteries are a perfect replacement for lead-acid batteries, and they are the first choice for grid-connected peak shaving, off-grid energy storage, photovoltaic energy storage, UPS, data center and other industries.