Methods and reports for improving battery performance in low temperature

environments

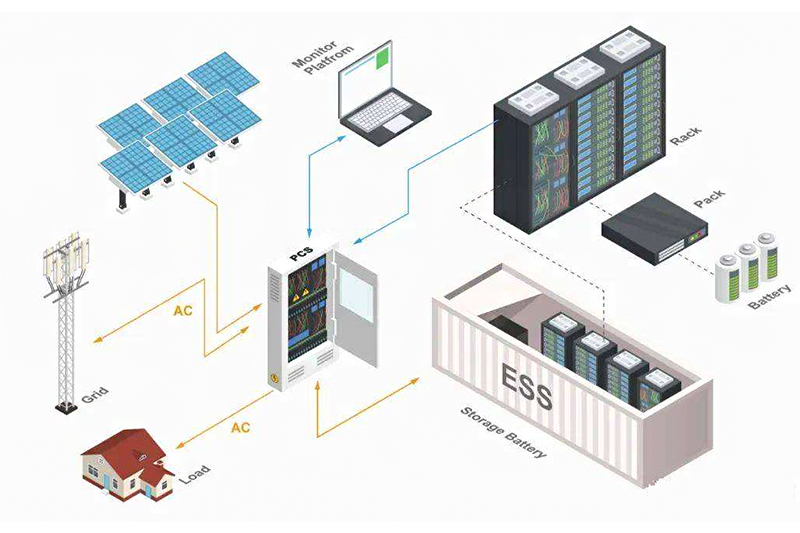

Storing energy through rechargeable battery technology has since enabled

our digital lifestyles to be fully powered, and on the one hand, renewable

energy sources can be integrated into the grid. However, battery function in

cold conditions remains a challenge, prompting research to improve the

low-temperature performance of batteries.

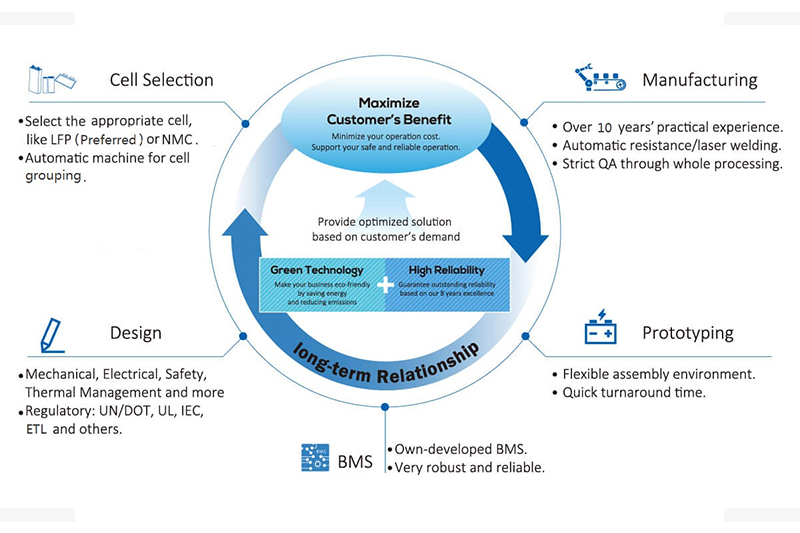

SES Power has successfully launched lithium iron phosphate batteries that

can be used at -60 degrees Celsius and can be discharged at a rate of -40

degrees Celsius. They have been used in cold and high temperature areas, such as

outdoor power tools, electric sleds, electric Snow removal vehicles, outdoor

monitoring, power grid monitoring, etc. But we are still concerned with

different routes for improving the low temperature performance of lithium

batteries.

The study found that aqueous batteries (in liquid solutions) were better

than non-aqueous batteries in terms of discharge rate (a measure of energy

released per unit time) at low temperatures.

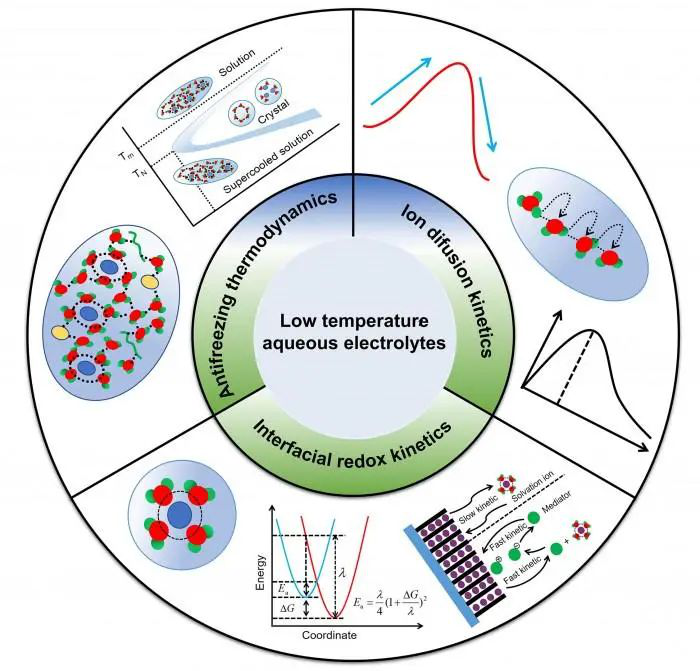

New research by engineers at the University of Hong Kong, recently

published in the journal Nano Research Energy, proposes optimal design elements

for aqueous electrolytes for low-temperature aqueous batteries. The study

examined the physicochemical properties of aqueous electrolytes (determining

their performance in batteries) based on several metrics: phase diagrams, ionic

diffusivity, and the kinetics of redox reactions.

The main challenge of low-temperature aqueous batteries is that the

electrolyte freezes and ions diffuse slowly, resulting in sluggish redox

kinetics (electron transfer process). These parameters are closely related to

the physicochemical properties of the low-temperature water-based electrolytes

used in batteries.

Therefore, to improve the performance of batteries in cold conditions, it

is necessary to understand the response of electrolytes to cold (-50 oC to -95

oC/-58 oF to -139 oF). "In order to obtain high-performance low-temperature

aqueous batteries (LT-ABs), it is important to study the temperature-dependent

physicochemical properties of aqueous electrolytes to guide the design of

low-temperature aqueous electrolytes (LT-AEs)," said study author and associate

professor Yi-Chun Lu. "

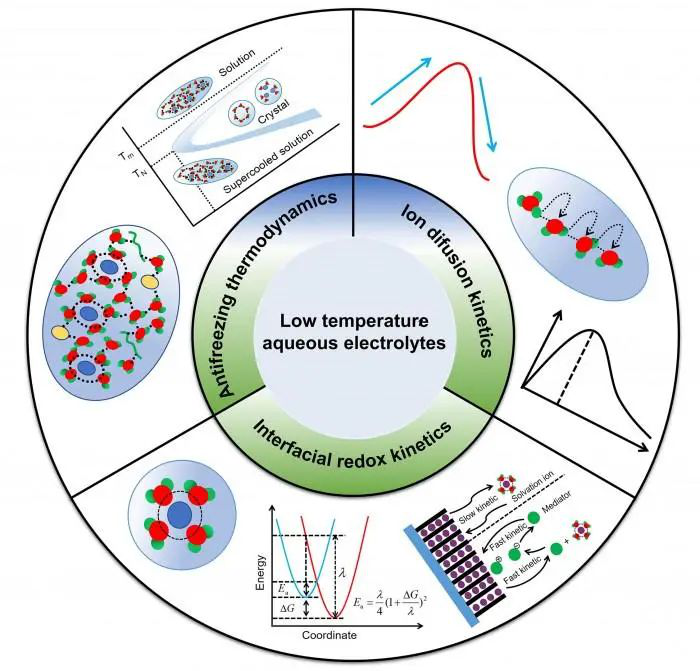

The figure shows the design strategy of water electrolyte, including

antifreeze thermodynamics, ion diffusion kinetics, and interfacial redox

kinetics.

The researchers compared various LT-AEs for energy storage technologies,

including Li+/Na+/K+/H+/Zn2+-batteries, supercapacitors, and flow battery

technologies. This study collates information from many other reports on the

performance of various LT-AEs, such as antifreeze hydrogel electrolytes for

Zn/MnO2 water batteries; and ethylene glycol (EG)-H2O hybrid electrolytes for Zn

metal batteries.

They systematically studied the equilibrium and nonequilibrium phase

diagrams of these reported LT-AEs to understand their antifreeze mechanisms. The

phase diagram shows the changes in the electrolyte phase at different

temperatures. The study also examined the electrical conductivity of LT-AEs as a

function of temperature, electrolyte concentration, and charge carriers.

Study author Lu predicts that "an ideal antifreeze water electrolyte should

not only exhibit a low freezing temperature Tm, but also possess a strong

overload capability," that is, the liquid electrolyte medium remains liquid even

at sub-freezing temperatures, enabling ultra-low temperature ion transport.

The study authors found that most of the LT-AEs that enabled the battery to

operate at ultra-low temperatures exhibited low freezing points and strong

supercooling capabilities. Furthermore, "strong overload capability can be

achieved by increasing the minimum crystallization time t and increasing the

ratio of the glass transition temperature and freezing temperature (Tg/Tm) of

the electrolyte".

The charge conductivity of the reported LT-AEs for batteries can be

improved by reducing the energy required for ion transfer to occur, adjusting

the concentration of the electrolyte, and selecting certain charge carriers that

promote fast redox reaction rates.

"Lowering the diffusion activation energy, optimizing the electrolyte

concentration, selecting charge carriers with low hydration radii, and designing

a cooperative diffusion mechanism would be effective strategies to improve the

ionic conductivity of LT-AEs," Lu said.

In the future, the authors hope to further investigate the physicochemical

properties of electrolytes that can help improve the performance of water

batteries at low temperatures. "We hope to develop high-performance

low-temperature water batteries (LT-ABs) by designing water-based electrolytes

with low freezing temperature, strong supercooling capability, high ionic

conductivity, and fast interfacial redox kinetics," Lu said.